Corporate Laser Printer Maintenance Agreements

and

Preventative Maintenance Program

|

Color Lasers

Component Testing

Jet Admin

Supplies

|

Planning

-

Planning is the key to a successful maintenance program. High volume printers

are identified, giving special attention can be given to those most frequently

used devices. Scheduled maintenance is setup for non-peak printing times,

eliminating interfere with mission critical operations. Using a

proprietary software tool, we are able to predict and detect failures before

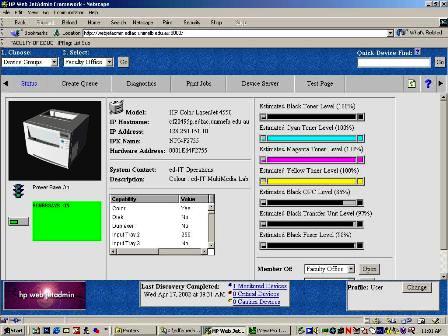

they adversely effect your business. Site-Map - We use your floor plan, or one of our own to develop a reference chart for each unit under maintenance. This will help expedite calls and decrease off-line time. Contact us for a free sample chart we employ to identify your printers. Jet-Admin -

Optionally, we will setup or assist your network administrators in

Jet-Administration software setups. Since many network printers have IP

addresses, the printers can actually report conditions like low toner, maintenance

needed scheduling and downed printers due to a paper-jam or other error condition.

Setting up Jet-Administration software will allow the computers to page our technicians

before serious problems occur! Supplies - Not all toner cartridges are the same. We recommend using original manufacturers' toner cartridges. Although there are many fine refurbished toner cartridge providers, manufacturers do provide the most consistent level of overall quality. If you do use refurbished cartridges, be sure that the quality is guaranteed. Some cartridge refurbishers just refill the cartridge with toner, leaving a worn drum inside. This can cause lines down the sides of the page on the printouts. In addition, heat distorted plastic parts and a non-lubricated drum bushing can cause premature motor failure, toner spills, and electrical shorts. Maintenance Agreements - A contract written in simple English and without legal jargon is easier to understand and contains all the necessary essential terms of the maintenance agreement. Preventative maintenance can be scheduled from 1 to 4 times per year or not at all. A list of covered equipment is attached to the maintenance agreement and is itemized by cost per printer. For a maintenance agreement quote please call or write and include the make and model of each piece of equipment you want to cover. Currently we also offer 'Executive Agreements' that cover end user support, supplies, computers and networks as well. |

Here

is What We do During a Preventative Maintenance Visit:

Ventilation

– We check fans and ambient noise levels. We choose to replace noisy fans

instead of lubricating them. This is done because heat may have also damaged the

integrity of the windings within the fan motor. A bad fan can cause excessive

heat, damaging sensitive electronic circuitry. Loose screws can cause

noise, dropping into the mechanism as they completely free themselves,

so we make sure that screws are always tightened after parts are replaced. In

addition, we will advise you of potential damage due to location of printers and

over-all room temperature.

Fusers

– We check the fuser / fixing assembly. Fusers melt the toner to the paper,

thus ‘fixing’ it. We check the fuser and fuser wand to excessive toner

build-up. Changing the wand whenever you replace the toner cartridge will

greatly extend the life of the fuser. If the fuser is bad, or excessive wear is

noted, we choose to replace the fuser entirely and not just replace parts. This

greatly reduces down time and a factory replacement contains all new parts, not

just a replacement of the defective ones.

Print Quality

- Print quality is what every user expects to be perfect. If imperfections are

noticed, we will identify the problem and correct it by replacing necessary

parts. If a defective cartridge is to blame, we will notify your staff as to the

nature of the cartridge defect.

Paper Trays

– We check input and output trays for excessive wear. Input and output trays

are often neglected when servicing laser printers. Simple cleaning goes a long

way in preventing a tray failure.

Rollers

– We clean and refurbish pickup and transfer rollers. Using patented

chemicals, we often extend the life of the rollers in your printers. This reduces

down time as well by contributing to overall lower maintenance costs overall. If

excessive wear or hardness is noted, we always replace pickup rollers or exit

rollers with factory new assemblies. Separation pads are always examined and

usually replaced. These are often made of cork and help insure that just one

piece of paper is picked up at a time.

Corona Wires

– We keep corona wires clean. Dirty corona wires often cause imperfections in

print quality. Cleaning the corona wires takes very little time, but can

improve print quality dramatically. Corona wires are often contained within the

toner cartridge and are extremely delicate. Please be careful if you choose to

do this yourself!

Optical Assemblies – We help keep lenses clean. Depending on the laser printer, lenses

can be exposed to environmental pollutants and can create print quality

problems. When practical, we clean these lenses to insure the best print quality

with EPA approved compressed gases. If serious print quality is caused due to

contaminants in a sealed laser scanner assembly, the assembly is replaced with

one that is either factory cleaned, refurbished, or a completely new one. Internal mirrors

contained in these scanners takes some time to get to, so it is almost always

faster to replace the assembly than to clean the mirrors in the field.

Lubrication

– We will lubricate necessary gears and mechanisms. Noise during printing can

be reduced by lubricating critical parts. In addition, some manufacturers

recommend lubricating drive gear clusters. We use factory recommended lubricants

whenever possible. When lubrication is recommended and no particular lubricant

is specified, we use patented lubricants of a viscosity we familiar with to have the most

positive effect on the gear mechanisms.

Air Filters – We will replace badly clogged ozone filters. Ozone filters collect a lot of dust and excessive heat can develop within the printer. Our technicians will replace and show your staff where these filters are and how easily they are to replace.

Toner Spills – We check toner cartridges when we see toner spills. Toner spills can cause poor print quality and electrical shorts. Our technicians use 3M brand vacuum cleaners that contain toner quality micro filters to insure OSHA standards are maintained within your facilities. Although sensors are normally cleaned during standard preventative maintenance, special attention is placed on cleaning sensors and optics with EPA approved compressed gas whenever toner spills are cleaned up.

***

About our Technicians - Our technicians are factory authorized and carry a minimum of 2 years

experience. In addition, they are required to have both an extensive electronics

background and computers and networking experience.

San Francisco Computer Repair is proud to be an Elite Service Center for Brother, Canon, Hewlett Packard, Okidata, QMS-Minolta, IBM, Printronix, Panasonic, and many others. We carry a complete stock of parts for these printers and our 95% customer satisfaction rating with Canon is one of the highest in the country. Canon based engines are in 90% of the laser printers sold by Hewlett Packard and other manufacturers and, out of 10,279 complaints of poor service reported to the Bay Area Better Business Bureau in the last year, our company received none! It is no wonder that many companies call us the best-kept secret among the San Francisco area repair businesses. So when it comes to repairing or buying a printer, rest assured we do it right the first time.